Toyota ev Batteries – Introducing The Best Next Generation Solid-state batteries

Toyota ev Batteries – Introducing The Best Next Generation Solid-state batteries

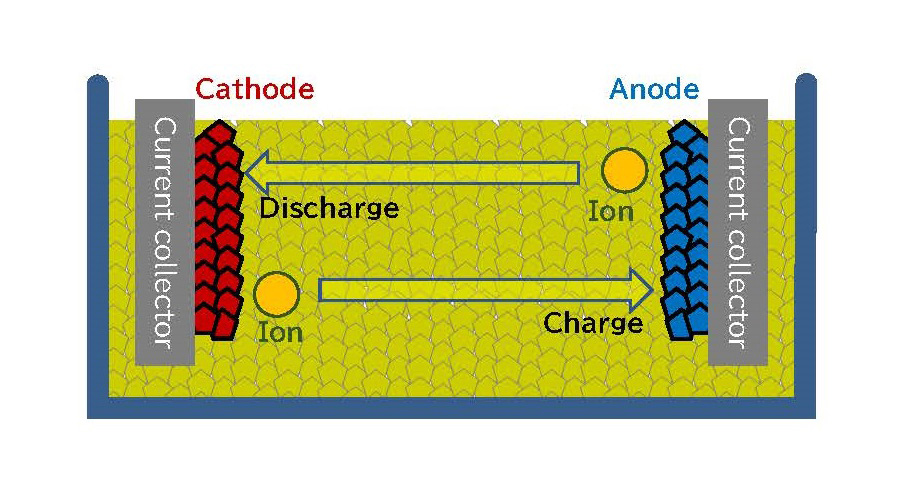

Toyota has been working on solid-state batteries for many years, and it is now reportedly close to a breakthrough. Solid-state batteries are next-generation batteries that offer a number of advantages over traditional lithium-ion batteries, including:

- Higher energy density: Solid-state batteries can store more energy per kilogram than lithium-ion batteries, which means that electric vehicles with solid-state batteries could have a longer range.

- Longer lifespan: Solid-state batteries have a longer lifespan than lithium-ion batteries, which means that they would need to be replaced less often.

- Improved safety: Solid-state batteries are less flammable than lithium-ion batteries, which makes them safer to use.

According to a recent news article by MSN, Toyota is on the verge of a breakthrough in the mass production of solid-state batteries. The company is targeting commercialization of solid-state batteries by 2027-28. If Toyota is successful in commercializing solid-state batteries, it would be a major breakthrough for the electric vehicle industry. Solid-state batteries could make electric vehicles more affordable, practical, and appealing to consumers.

As per Driving.co.uk, Toyota aims to have solid-state batteries ready for commercial sale as early as 2027. The automaker claims that these new batteries will offer up to 750 miles of range on a single charge. Additionally, the charging time will be less than 10 minutes for a 10-80% state of charge (SoC) using these new solid-state batteries. This is a significant improvement over lithium-ion batteries.

According to Business Standard, if successful, Toyota’s solid-state batteries will double the range of EVs up to 1,200 km and reduce the charging time to 10 minutes or less. The article also states that solid-state batteries are lighter than lithium-ion batteries, which could make electric vehicles more efficient and improve their performance.

Overall, solid-state batteries have the potential to revolutionize the electric vehicle industry. Toyota’s breakthrough in the development of solid-state batteries could make electric vehicles more practical and appealing to consumers. With longer driving ranges, faster charging times, reduced weight, and increased safety, solid-state batteries could be the game-changer that the EV industry has been waiting for.

Toyota ev Batteries

Toyota, the world’s leading automaker, stands on the verge of a game-changing development with the potential to reshape the global automotive industry – the large-scale production of solid-state batteries.

Solid-state batteries, long hailed as a transformative technology for electric vehicles (EVs), offer the promise of addressing concerns related to charging time, energy capacity, and safety. This breakthrough could pave the way for a future in which EVs surpass their internal combustion engine counterparts.

Toyota’s ambitious vision involves powering EVs with solid-state batteries capable of delivering a remarkable range of 1,200 kilometers, effectively doubling the current EV range. Moreover, charging times are set to be dramatically reduced to a mere 10 minutes or less. This audacious plan comes on the heels of a recent battery material innovation that may enable Toyota to commence solid-state battery production by 2027 or 2028. Nevertheless, the journey towards this electrifying future is fraught with challenges.

Toyota ev Batteries: Challenges

Challenges in Scaling Up The process of mass-producing solid-state batteries is intricate and expensive. These batteries exhibit high sensitivity to humidity and oxygen, demanding precise handling to avert degradation. Furthermore, the maintenance of battery layers necessitates precise mechanical pressure application to prevent the formation of dendrites, which could trigger short circuits. Nevertheless, Toyota’s engineers are steadily advancing toward overcoming these challenges, fostering optimism about the company’s potential to meet its production targets.

Revolutionary Potential

The implications of successfully scaling up solid-state battery production extend well beyond the automotive sector. From an environmental standpoint, global efforts to decarbonize could receive a substantial boost. The enhanced range and shortened charging duration might make electric vehicles more attractive to consumers, potentially expediting the transition away from fossil fuel-powered vehicles. Additionally, the demand for solid-state batteries could stimulate innovation and investments in battery technology, opening doors for further advancements in energy storage and sustainable transportation solutions.

Balancing Optimism with Caution

It’s undeniable that the path to mass-producing solid-state batteries is fraught with obstacles. The heightened sensitivity of these batteries to environmental factors and the precise mechanical pressure requirements for their assembly pose formidable challenges. Achieving successful mass production will necessitate not just extensive research and development but also substantial financial investments. Nevertheless, the unwavering commitment of companies like Toyota to this technology offers promise for a future in which electric vehicles become the norm rather than the exception.

Source : MSN

Toyota News Release on Toyota ev Batteries

“Idemitsu and Toyota Announce Beginning of Cooperation toward Mass Production of All-Solid-State Batteries for BEVs“

Oct. 12, 2023

Idemitsu and Toyota Announce Beginning of Cooperation toward Mass Production of All-Solid-State Batteries for BEVs

Beyond Zero News Release Presentation Management Message from Management Koji Sato Battery Carbon Neutrality

Idemitsu Kosan Co.,Ltd. (Idemitsu) and Toyota Motor Corporation (Toyota) announced today that they have entered into an agreement to work together in developing mass production technology of solid electrolytes, improving productivity and establishment a supply chain, to achieve the mass production of all-solid-state batteries for battery electric vehicles (BEVs). Through this collaboration, the two companies, which lead the world* in the fields including material development relating to all-solid-state batteries, seek to ensure the successful commercialization of all-solid-state batteries in 2027-28―as announced at the Toyota Technical Workshop in June 2023―followed by full-scale mass production.

Combination of Idemitsu’s social implementation of energy one step ahead and materials and Toyota’s multi-pathway approach is promoting BEV development, which is a vital option in the move towards carbon neutrality. As for next-generation batteries which support an evolution of BEVs, Idemitsu has been working on research & development on elemental technologies for all-solid-state batteries since 2001, while Toyota started in 2006.

This collaboration focuses on sulfide solid electrolytes, which are seen as a promising material to achieve high capacity and output for BEVs. Sulfide solid electrolytes are characterized by softness and adhesiveness to other materials, which is suitable for battery mass production.

To prepare for full-scale mass production, both companies have established a task force consisting of dozens of members and will proceed the collaboration as follows:

Details of collaboration

Phase 1

Development of sulfide solid electrolytes and preparation for a large pilot facility

- Through feedback and development support from each other on each company’s technical area, both Idemitsu and Toyota will work together on creating better sulfide solid electrolytes with attention to quality, cost, and lead times, which both companies believe will realize mass-production demonstration of sulfide solid electrolytes using an Idemitsu pilot facility.

Phase 2

Mass production using a large pilot facility

- Through construction and startup of a large pilot facility, Idemitsu will promote sulfide solid electrolyte manufacture, and then will obtain mass production technology.

- Toyota will promote development of both all-solid-state batteries which sulfide solid electrolytes are used and BEV development in which the batteries are incorporated, and then will ensure market launch of BEVs with all-solid-state batteries in 2027-28.

Phase 3

Study of future full-scale mass production

- Based on the results of Phase 2, both companies will study of future full-scale mass production and commercialization.

Idemitsu has also been developing production technologies of lithium sulfide which is an intermediate material for solid electrolytes, using by-products which are generated in the course of petroleum refining. And through such development, it has been working on development of mass production technology on sulfide solid electrolytes, aiming to establish a stable supply system. Further, the company is steadily increasing the capacity of its small pilot facility―announced in June 2023―and is proceeding construction plan of a large pilot facility―announced in April 2022―, which will contribute to commercialization of all-solid-state batteries in 2027-28.

Through combination of both companies’ material development technologies, Idemitsu’s material manufacture technologies and Toyota’s battery processing and assembly technologies which is obtained through BEV development, both companies will aim to realize mass production of both solid electrolytes and all-solid-state batteries suitable for global widespread use. Both companies, working together across industries, will contribute to global carbon neutrality, and will lead the future with technologies created in Japan.

EV Battery Replacement Cost & New Toyota 1400 km Battery